Managers also use these costs to evaluate the efficiency of the production process and identify waste. The total materials costs for the period (including any beginning inventory costs) is computed and divided by the equivalent units for materials. The total of the cost per unit for material ($1.17) and for conversion costs ($2.80) is the total cost of each unit transferred to the finishing department ($3.97).

2 Explain and Identify Conversion Costs

As machinery and equipment become older and less efficient, this can affect the number of goods produced within a particular time. This can lead to higher conversion costs as it may require additional time or resources to produce the same amount of goods. Automation can increase manufacturing flexibility by allowing manufacturers to switch between products or product lines quickly.

Understanding Conversion Costs in Cost Accounting

If it is not, such as just one or two conversions from 1,000 clicks, consider pausing the keyword. You see which of your campaigns have the lowest cost per conversion, preferably compared to high values for those conversions, and focus your efforts and budget on them. Remember that you can CARES Act define conversion however you want, such as the number of sales and number of operating leverage dol formula + calculator signups for your email list. The following are some of the most commonly used conversion metrics when assessing conversion cost. Each has its own example of how you would assess conversions with your given definition for the conversions.

Implement Supply Chain Optimization – Some Strategies to Reduce Conversion Costs

Let’s say your department cooks dumplings (a prior department prepared the dumplings; your job is just to cook them). Outsourcing production can increase the risk of intellectual property theft or infringement. If the contract manufacturer has access to the outsourcing company’s proprietary information, there is a risk that this information could be misused or shared with competitors. This can result in increased costs for legal fees and damage to the outsourcing company’s reputation. Automated processes can improve workplace safety by reducing the risk of accidents and injuries.

- Conversion costs include the direct labor and overhead expenses incurred as raw materials are transformed into finished products.

- By considering these diverse perspectives and insights, we can gain a comprehensive understanding of the nuances surrounding the total conversion cost without explicitly stating the section title.

- This can lower the total conversion cost of producing a product for the outsourcing company.

- It is the direct labor plus any manufacturing overheads needed to convert raw materials into a finished product.

- The conversion cost is a significant determinant of the pricing decision for the finished product.

Direct Labor

- As mentioned earlier, outsourcing production can increase transportation costs.

- Therefore, one difference between the two concepts is that manufacturing overhead is only included in conversion costs.

- They may not be as visible as direct costs, but their impact on profitability is undeniable.

- The calculation of the cost of sales, which is reported on the income statement, also depends on the conversion cost.

- With the insights provided in this article, you can now efficiently calculate your conversion costs and optimize your production processes for greater profitability.

- Businesses must incorporate these costs into pricing models to maintain profitability and competitiveness.

For example, suppose a company outsources the production of a product to a contract manufacturer. In that case, the contract manufacturer may be responsible for purchasing and maintaining equipment, paying for utilities, and handling other overhead expenses. This can lower the total conversion cost of producing Accounts Payable Management a product for the outsourcing company. The calculation for prime costs includes the amounts spent on direct materials and direct labor.

Conversion Cost : Meaning, Formula, Types and Importance

- Analyzing conversion cost variance involves investigating the reasons behind the variance and identifying the specific cost components that contributed to it.

- This leads to the very-important term total equivalent units (which I will sometimes abbreviate as TEU).

- Both provide an overview of the company’s expenses that affect the production process and help the company make favourable financial decisions.

- That removes the portion of beginning WIP units that were completed last period.

- Manufacturers can improve workforce productivity by providing training and development programs, setting clear expectations and goals, and implementing performance management systems.

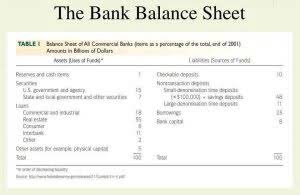

They may not be as visible as direct costs, but their impact on profitability is undeniable. During June, Excite Company’s prime cost was $325,000 and conversion cost was $300,000. Compare the conversion cost per unit with the previous periods, the industry average, or the target cost to evaluate the performance and efficiency of the production process. Manufacturing cost is the cost that company spends to support the production process but they cannot allocate to each product. They are the indirect cost that incurs to support the manufacturing, but it is very challenging to apply the cost to each production unit. Direct materials pertain to cost of items that form an integral or major part of the finished product.

1.3 Complication #2: Non-uniform Consumption of Product Costs

By optimizing the conversion process, businesses can achieve higher conversion rates and maximize their return on investment. Conversion costs play a key role in determining the Cost of Goods Sold (COGS), influencing the pricing strategy. Businesses need to set prices that not only cover conversion costs but also ensure conversion costs profitability and competitiveness in the market. Samsung has a cell phone production unit with a production capacity of 10,000 daily it incurs day-to-day expenses to keep its business running. The company wants to know its conversion cost from the following mentioned information.

Reduced Energy Consumption – How Does Automation Affect Conversion Cost?

Conversion costs are the labor and overhead expenses that “convert” raw materials into a completed unit. Each department tracks its conversion costs in order to determine the quantity and cost per unit (see TBD; we discuss this concept in more detail later). Conversion costs are restricted to direct labor and manufacturing overhead, which are needed to convert raw materials into completed products.

Leave a Reply